In almost all industries, Tri Elektronik offers a number of advantages to its users by opening a new era in marking with Inkprint printing method.

‘If you use the Inkprint Method, no one can tear off your brand from your product!’

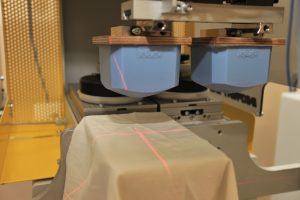

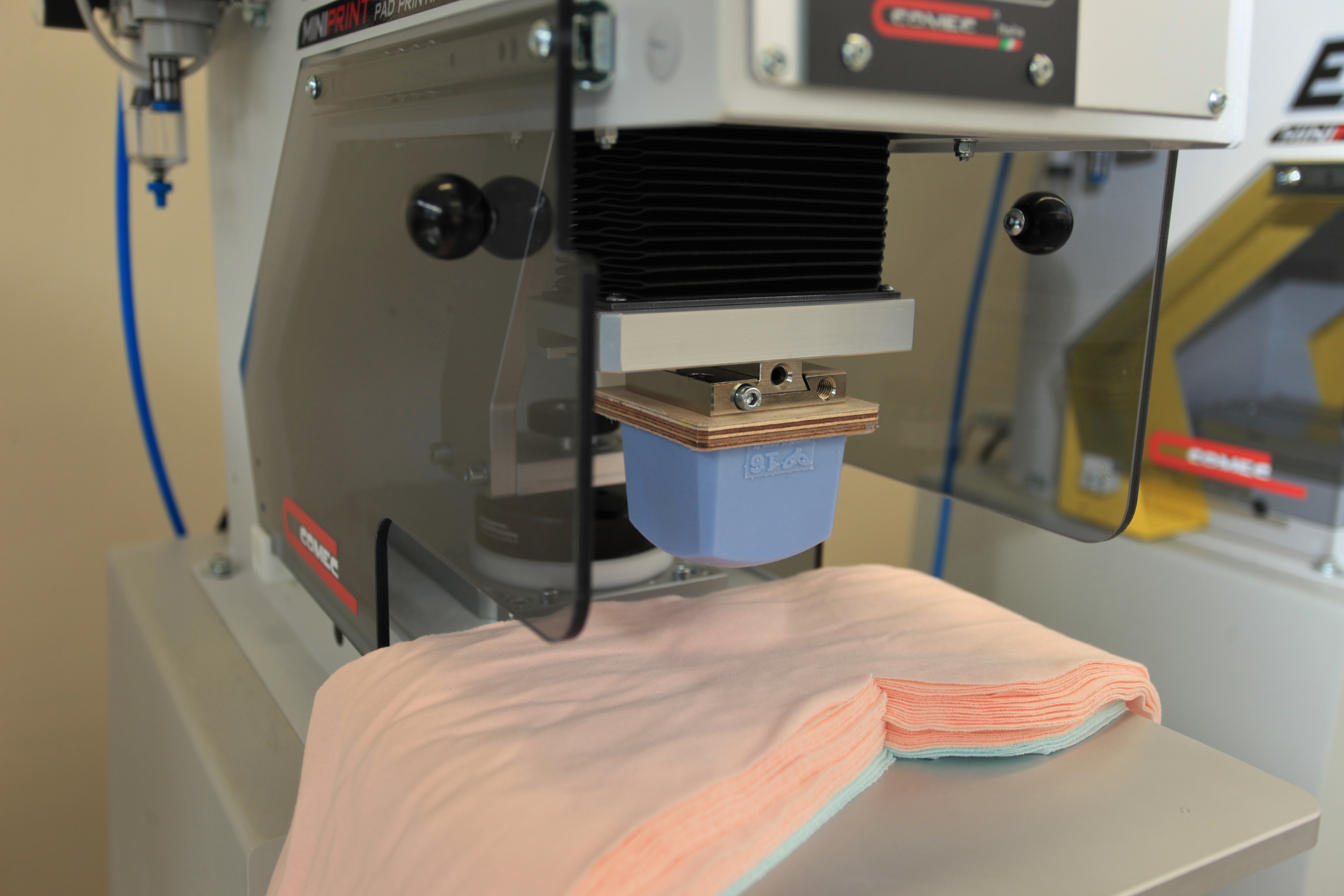

Inkprint is a tagless printing and washing instruction printing method in textiles which can be applied just before shipment of finished products such as seamless clothing, underwear, combed, t-shirt, shirt, socks, sportswear, swimwear and hat. The need for sewing labels in the textile sector has been eliminated with the fact that inkprint printing machines can print directly and permanently on the fabric. Inkprint Labelled Marking is resistant to washing, flexing and rubbing and does not shine on the fabric. The product can be printed in one color and two colors.

I would like to underline that; we pay great importance to the health issue where the consumer becomes more aware and approaching with great sensitivity. Special textile ink is our main product in Inkprint Tagless Printing method. Our inks are manufactured in compliance with RoHS directives and Toy standards, and contain no heavy metals or harmful substances threatening human health. There is no harm in contacting the user, it does not harm and it does not contain any carcinogenic substances. We also have all test reports and declarations. We provide these documents to companies who want. After printing on the product, it can pass OEKOTEX tests when sent to the test. Inks with ECO PASSPORT certification are also available.

‘Low printing cost with fast printing method’

Inkprint Unlabeled Marking has many advantages to the user. Let me briefly talk about these highlights. First of all, the use of this machine saves time and labor. For example, consider a one-day printing process. In the morning, before printing, there is about ten minutes of preparation for the necessary equipment, such as paint. After this process, if the brand, size or content will not change, you can continue printing until the end of the day. The printing has no waiting or drying process. Therefore, depending on the professionalism of the operator, you can print approximately 800 to 1200 products per hour. This means a high production rate, such as 5,000-8,000 product prints, with breaks and downtime within a day.

‘You can pay off the machine you bought in just 5-6 months!’

The price of our machine varies between 2,950 Euro and 3,880 Euro depending on accessories added. Considering the savings in cost, time and labor, I can say that it is a machine that will make profit for the user in the short term with a certain capital.

Consider like that the daily production of an average sized continuous and serial workshop is around 5,000-5,500 pieces. And they can meet their daily needs with a single inkprint machine. In addition, sewing speeds are increased because they do not lose time to sew labels, and an employee will be less. With a monthly production of approximately 120 thousand units, you can pay off the machine you bought in 5-6 months.